Our most common inspection tables have a stainless steel top, powder-coated steel frame and table that includes a galvanized roller, and LED light fixture. Inspection tables are used to provide a flexible way to inspect or assemble parts. They have an adjustable height and overhead lighting that guarantees a proper part inspection. A discharge chute, rollers, shelves and more can be added and built to your specifications.

An adjustable tray mounted at the end of a conveyor not only reduces spillage by positioning the box closer to the conveyor; it also helps to ensure that boxes stay clean and dry by keeping them off the floor.

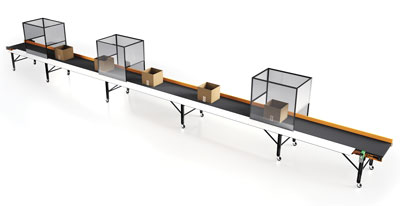

Preventing pile-ups at the end of a conveyor is easy with this adjustable angle cart. Placed at the end of a conveyor, this easy-to-adjust cart allows parts to slide away from the end of the conveyor. Not only does this help protect parts from being damaged by oncoming parts, it also helps to prevent parts from being drawn around and into the conveyor mechanism. Available in Stainless Steel, painted steel or aluminum. Wide range of sizes available.

This free-standing stainless steel top, pained steel frame table includes a galvanized roller, LED light fixture, and two shelves.

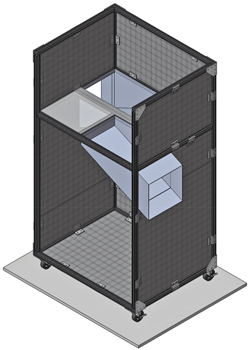

This enclosure has two chutes - one for good parts and one for bad parts. Black-coated mesh panels and a Lexan shelf keep parts contained.

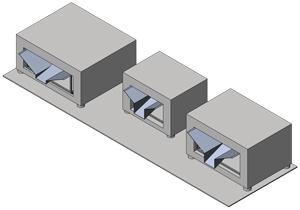

We can build custom chutes. Provide us the make and model of your injection molding machine. These shown are free-standing stainless steel chutes with a painted steel sub-base.

This part diverter is mounted under the press and includes a custom chute.

Delrin-lined work tables can be added to almost any EMI conveyor system.