No matter what your application needs are, EMI can design the perfect hopper for your EMI conveyor.

EMI offers a complete line of Accumulation Hoppers. They are available in a wide selection of capacities, sized to fit belt conveyor widths 6“ to 48“. This low-cost, side-feed, under-press hopper eliminates the need for an under-press conveyor. Use a polycarbonate cover on hoppers to keep contaminants out!

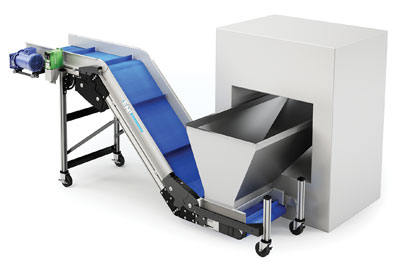

Some extra-large hoppers need legs to help support their weight and prevent the conveyor from tipping over. The legs on this hopper have castors to allow it to be easily moved.

Soft lining on the inside walls of this hopper assists in preventing cosmetically delicate parts from being scratched as they are fed into the hopper.

This under-the-press EAF model has an optional leg stand.

Extra-large hoppers such as these, are an excellent way to assure complete part containment when feeding parts into bowl feeders, grinders, etc.

Side-mounted castors allow the conveyor to sit at its lowest possible height, butting against the press to ensure maximum hopper reach into the press.