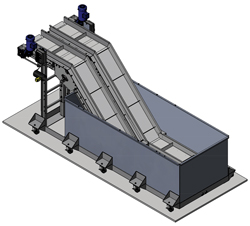

Water-cooling conveyors are an excellent way to cool thick-walled parts as they are being transferred to another conveyor or work station. Customized, flat-to-incline conveyors and water holding tanks provide a soft landing and maximum cooling. Units are available in a wide choice of widths and lengths. An indexing option is also available. Tank and conveyor specifications are the same as those listed below for standard Submersible Conveyors.

A wide choice of options allows water-cooling conveyors to be customized to suit specific application needs. This Submersible Conveyor, used in conjunction with a robot, has an elevated floor stand that raises it to meet the robot's release height. Heavy-duty castors allow it to be moved easily within the plant.

For parts that need maximum cooling, heat exchangers can be mounted to the sides of water bath conveyors to lower the temperature of the water in the water tank.

This 36-inch deep Wash Tank Conveyor is used to cool parts by immersing them in water. A stainless steel hopper keeps parts contained. White PVC belting with 1.5" cleats have .25" holes to allow drainage.

Parts drop into the large tank and then are slowly brought up two Stainless Steel KKI Conveyors.

This submersible conveyor has been customized with a containment hopper and mobile floor stand for portability within the plant.