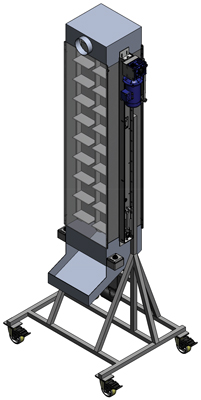

Part Relay Station uses an elevator to lower parts. This system was designed to lower parts from a robot with a limited vertical stroke. The parts were tall and delicate. Dropping them would cause damage, and moving them down an incline would cause them to tip over.

Tall, narrow parts had to be taken from a robot, lowered and then moved through a 90° turn to a secondary operation—without falling over. Because space was limited, an elevator was used to lower the parts. The parts are placed on the elevator, conveyor platform and then lowered. When the platform reaches the bottom, the conveyor platform activates and moves the parts to a 90° flat top, chain belt conveyor that moves the parts through the turn.

This easy-to-adjust, versatile belt conveyor application runs as a box fill at lower position, and then is raised to run as an indexing operator feeding conveyor. This particular lift raises from 24" to 40".

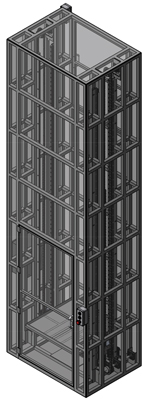

EMI can custom engineer a Chain-Driven Vertical Lifter with polycarbonate enclosure

EMI can custom engineer a Chain-Driven Vertical Lifter with polycarbonate enclosure This Part Elevator has Intralox belting, a cooling unit, polycarbonate rails and a cover

This Part Elevator has Intralox belting, a cooling unit, polycarbonate rails and a cover