Everyday polymers are surrounding us. From our cars to cell phones, polymers influence every aspect of our modern lives.

Working in the plastics industry leads others to believe that you are an expert on everything plastics. However, usually people know a lot about their area of expertise, but not as much about plastics as a whole. Someone may have expertise in polyethylene extrusion but know little about engineering resins.

We wanted to provide a brief overview of polymers to help better inform those looking to learn more.

What is a polymer?

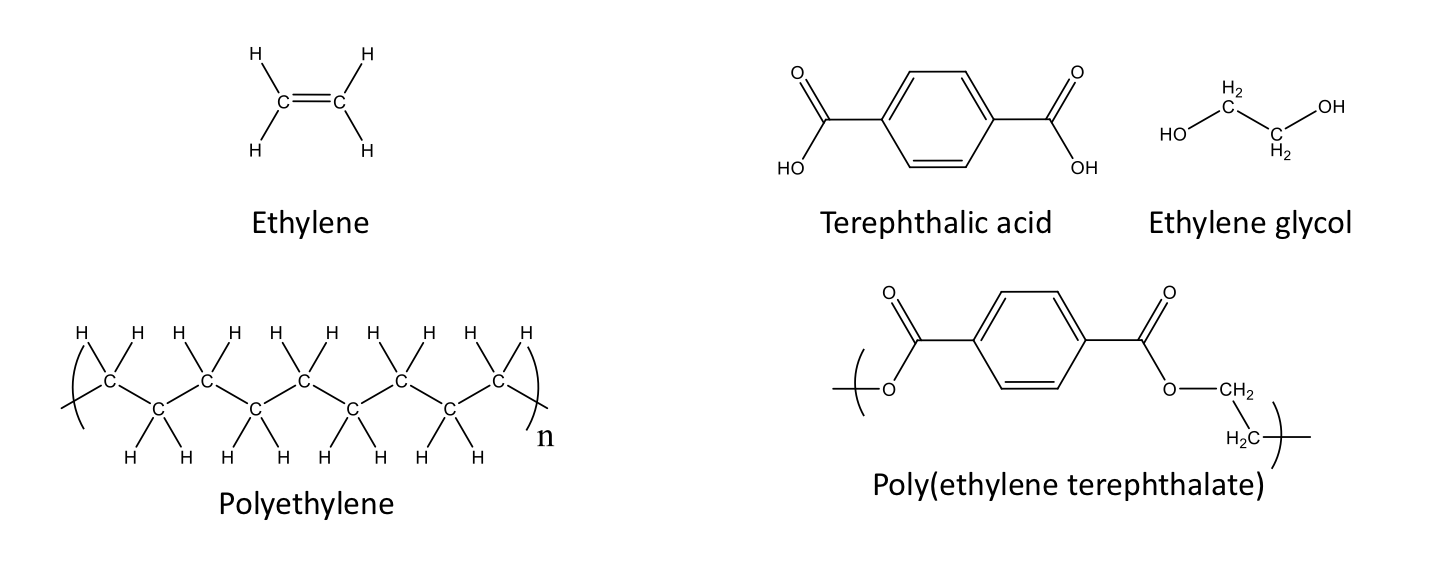

A polymer is a large molecule made up of many repeating subunits, called monomers. These molecules create long chains which group together and build up mass. The structure and properties of a polymer are dependent on the monomer making them up. Polyethylene (PE) and polyethylene terephthalate (PET) exhibit different properties because their monomers are different.

Because of this polymers exhibit a broad range of properties and are found in many industries besides plastics. Other applications of polymers can be found in pharmaceuticals, paints, textiles, and foods.

Where do polymers come from?

While some polymers are naturally occurring, most commercial polymers are synthetically produced. The majority of plastic resin is derived from petroleum or petrochemical byproducts.

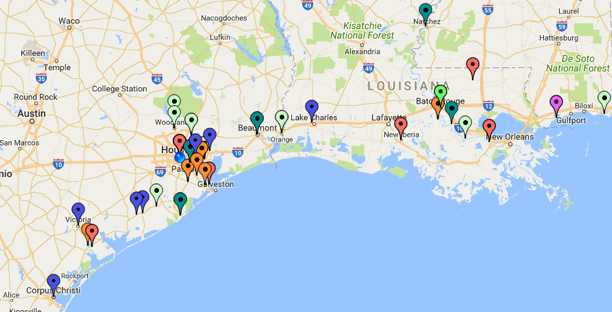

Because of this most US polymer production is concentrated along the Gulf Coast and other major petroleum production regions.

Since petroleum is the feedstock for polymers the price of resin is dependent on the price of oil. During summer months when demand for gasoline is high, and oil and resin prices increase.

Commodity Resins

The majority of plastic produced are commodity resins. These plastics are created on the scale of millions of tons per year and used in low-cost applications. Commodity resins have relatively low mechanical properties but suffice for most applications. Typical applications include food packaging, beverage containers, and consumer products.

- polyethylene (PE)

- polypropylene (PP)

- polystyrene (PS)

- polyvinyl chloride (PVC)

- polyethylene terephthalate (PET).

Engineering Resins

Applications that call for greater mechanical strength at lower volumes utilize engineering resins. These are higher cost parts where metals or other materials are being replaced (ex. mechanical gears and seals). Plastics parts are lighter, easier to manufacture, more chemically resistant than other materials.

- Nylon (PA)

- Polycarbonate (PC)

- Polysulphone (PSU)

- Polyoxymethylene (POM)

- Polyetheretherketone (PEEK)

The above sections are in no way exhaustive. There are hundreds of plastic types and formulations. Resin suppliers are a great resource when looking at specific applications for a material.

If you would like help on an equipment application, please contact us. See our products section for more information.