As processors, uptime is everything. In a perfect world, lines would be dedicated and materials would never need to change. But in reality, demands change and schedules move. This means material changeovers. Lots of them. Each changeover requires that the material handling system is emptied and cleaned to prevent contamination. If your equipment design is not optimized for cleaning, this can be quite a task. Even require disassembly. As a result, the risk of contaminating your next run is high.

If you do not have cleanouts in mind when buying equipment you may lose valuable uptime. And money.

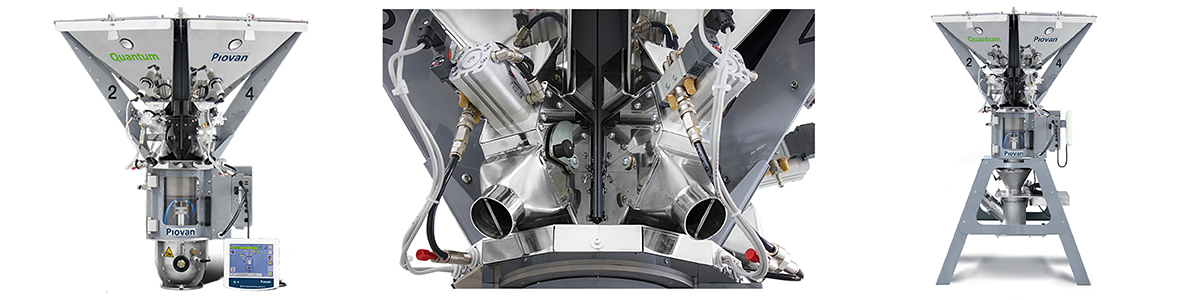

The Quantum blender from Piovan is designed to minimize your downtime and maximize your performance. It does this by coupling an easy to maintain design with the accuracy of a gravimetric blender.

In only sixty seconds the weighing hopper and mixer can be cleaned. Each of the Quantum's six dosing stations is removable by a single operator. This makes emptying and cleaning between runs easy. Easy-to-clean stainless steel contact surfaces minimize the risk of contamination. Even in the most stringent of applications. The Quantum is an example of how a product with a great design and new technology can help improve your process.

If interested in learning more about the Quantum see our products or contact us for more information.